+86-576-84352333

-

+86-18262333218

-

-

-

PRODUCTS

contact us

Tel:

E-mail:

Fax:

+86-523-88642288

Add:

Yuduo Industrial Zone, Jiangyan District, Taizhou City, JiangsuProvince

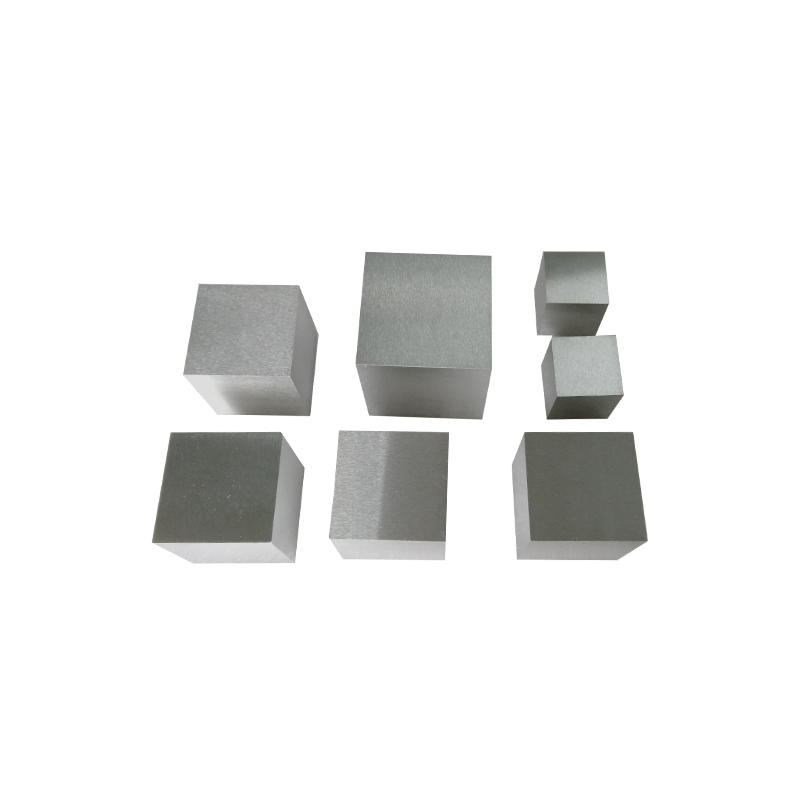

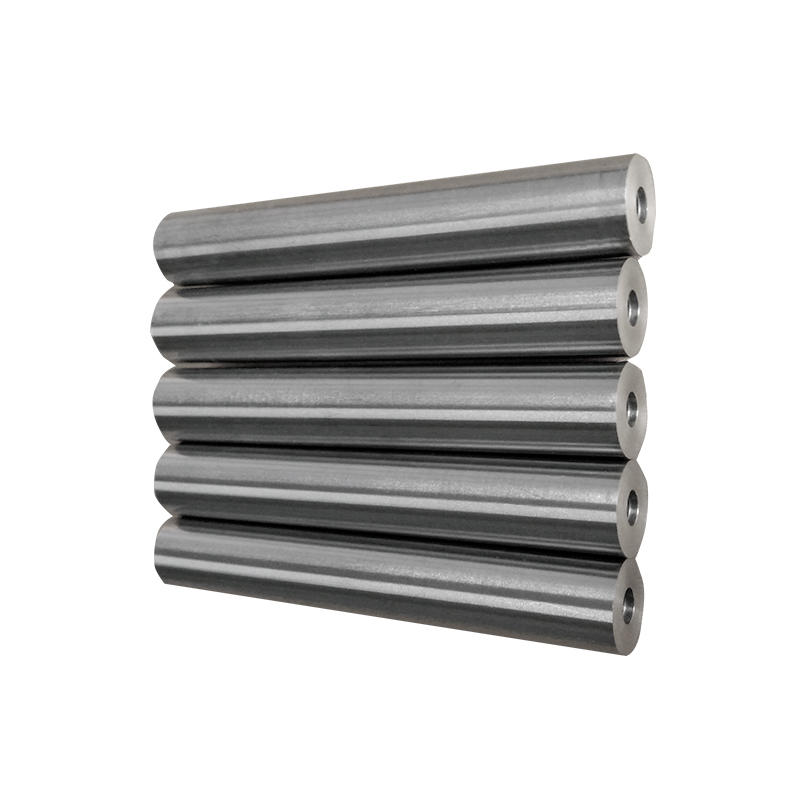

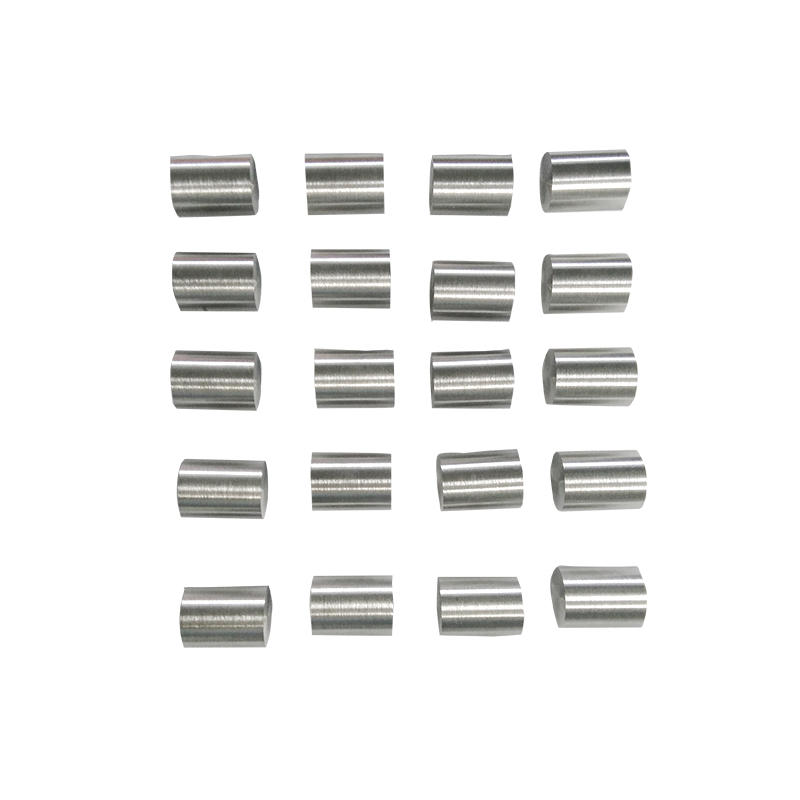

Explore the world of Tungsten Alloy, a category encompassing a diverse range of high-performance materials and components. Within this category, you'll find Tungsten Flow Ports, precision-engineered to facilitate controlled fluid or gas movement in industrial and scientific applications. Tungsten Alloy Special-Shaped Parts offer customized solutions for various industries, while Tungsten Alloy Counterweights ensure balance and stability in machinery and equipment. Tungsten Alloy Rings combine durability and style, while Tungsten Alloy Tubes excel in badness conditions. These materials and components, known for their exceptional strength, heat resistance, and reliability, play pivotal roles in aerospace, manufacturing, and more. Additionally, explore Molybdenum Deep Processing Products, showcasing versatile applications of this high-performance metal.

About

Taizhou Huacheng Tungsten And Molybdenum Manufacture Co., Ltd.

Taizhou Huacheng Tungsten and Molybdenum Products Co., Ltd. is a professional company that produces tungsten and molybdenum series products.

The company specializes in the production of tungsten and molybdenum special-shaped parts, high-density tungsten alloys, tungsten-copper alloys, and the research and development of new tungsten-molybdenum materials. Tungsten Alloy Suppliers and Custom Tungsten Alloy Material Manufacturers. The main products are:

● Tungsten

● Molybdenum strip

● Plate

● Electrode rod

● Tungsten and molybdenum crucible

● Molybdenum Piercing Mandrel

● TZM rare earth molybdenum

● Sodium tungstate

● Sodium molybdate

● Tungsten

● Molybdenum strip

● Plate

● Electrode rod

● Tungsten and molybdenum crucible

● Molybdenum Piercing Mandrel

● TZM rare earth molybdenum

● Sodium tungstate

● Sodium molybdate

Message Feedback

News

-

Molybdenum plates are available in various grades and specifications to suit different application requirements. Some co...

READ MORE -

Molybdenum plates possess several important properties that make them valuable for various applications: Strength: Molyb...

READ MORE -

Using molybdenum plates can offer several advantages over other materials:High Temperature Resistance: Molybdenum has a ...

READ MORE -

Tungsten alloy plates are suitable for use in harsh environments and under extreme conditions, including high temperatur...

READ MORE

Industry knowledge

How does the density of Tungsten Alloy compare to other materials, and how is it advantageous in weight-sensitive applications?

Tungsten Alloy is known for its exceptional density, which is significantly higher than that of many other materials. Here's how the density of Tungsten Alloy compares to other materials and why its high density is advantageous in weight-sensitive applications:

Density Comparison:

Tungsten Alloy has one of the highest densities among all known materials. Its density typically ranges from 16.5 to 18.75 grams per cubic centimeter (g/cm³), depending on the specific composition of the alloy.

For comparison, the density of lead is approximately 11.34 g/cm³, and that of steel is around 7.85 g/cm³.

Advantages in Weight-Sensitive Applications:

High Mass in Small Volumes: The high density of Tungsten Alloy allows for a significant mass to be achieved in relatively small volumes. This is advantageous in applications where weight needs to be concentrated in a limited space.

Reduced Size and Thickness: In weight-sensitive applications, designers can use Tungsten Alloy to achieve the same mass or shielding effect as a larger volume of a lower-density material. This enables the reduction of size and thickness in components or structures.

Enhanced Performance: Tungsten Alloy's high density is particularly valuable in applications where mass or weight plays a critical role in performance. For example, in aerospace, defense, and certain medical devices, the ability to achieve a specific weight target while maintaining structural integrity is crucial.

Improved Shielding: In radiation shielding applications, the high density of Tungsten Alloy makes it an excellent choice for attenuating X-rays and gamma rays. The compact size and weight efficiency of tungsten alloy shielding materials are essential in medical imaging and industrial radiography.

Balancing and Counterweights: Tungsten Alloy is commonly used in applications that require precise balancing or counterweights, such as in aircraft, race cars, and precision machinery. The high density allows for effective weight distribution in confined spaces.

Penetrating Power in Kinetic Energy Penetrators: Tungsten Alloy's high density is exploited in kinetic energy penetrators, where it provides increased penetration power due to its ability to concentrate mass in a small projectile.

Performance in High-G Environments: In aerospace and defense applications, Tungsten Alloy's high density contributes to its performance in high-G environments, providing stability and control.

Vibration Damping: Tungsten Alloy's high density contributes to its effectiveness in vibration damping applications, where the mass is strategically distributed to reduce vibrations and improve stability.

The high density of Tungsten Alloy makes it a preferred choice in weight-sensitive applications where achieving maximum mass or shielding effect in limited space is essential. The ability to concentrate mass in smaller volumes while maintaining structural integrity provides significant advantages in various industries, including aerospace, defense, medical, and precision engineering.

How effective is Tungsten Alloy in radiation shielding applications?

Tungsten Alloy is highly effective in radiation shielding applications due to its unique combination of properties, including high density and excellent attenuation of X-rays and gamma rays. Here are key reasons why Tungsten Alloy is widely used for radiation shielding:

High Density:

Tungsten Alloy possesses an exceptionally high density, typically ranging from 16.5 to 18.75 grams per cubic centimeter (g/cm³). This high density allows for the effective absorption and attenuation of ionizing radiation.

Attenuation of X-rays and Gamma Rays:

The high atomic number (Z) of tungsten (74) contributes to its strong interaction with X-rays and gamma rays. This results in efficient attenuation, reducing the penetration of radiation through the shielding material.

Compact Shielding Thickness:

The high density of Tungsten Alloy enables the production of compact shielding solutions. Thinner layers of tungsten alloy can achieve the same or even superior shielding effectiveness compared to thicker layers of lower-density materials.

Reduced Shielding Footprint:

Tungsten Alloy's ability to provide effective shielding in a compact form allows for the design of shielding solutions with a reduced footprint. This is particularly important in environments where space is limited.

Versatility in Shielding Design:

Tungsten Alloy can be easily machined or shaped into various forms, making it versatile for designing custom shielding solutions. It can be used in the form of sheets, plates, collimators, containers, and other configurations based on specific application requirements.

Medical Imaging and Radiation Therapy:

Tungsten Alloy is commonly used in medical applications, such as in the construction of collimators for X-ray machines and computed tomography (CT) scanners. It provides precise control over the direction and intensity of the X-ray beam.

Nuclear Medicine:

In nuclear medicine applications, Tungsten Alloy is used for radiation shielding to protect personnel and equipment from gamma radiation emitted during diagnostic and therapeutic procedures.

Industrial Radiography:

Tungsten Alloy is employed in industrial radiography for shielding personnel and preventing unwanted exposure to X-rays and gamma rays during non-destructive testing (NDT) and inspection processes.

Nuclear Power Plants:

Tungsten Alloy is utilized in nuclear power plants for radiation shielding purposes. It helps protect workers and equipment from the radiation generated during nuclear reactions.

Transportation of Radioactive Materials:

Tungsten Alloy containers are used for transporting radioactive materials. The dense shielding provided by tungsten alloy ensures that radiation exposure is minimized during transportation.

Dose Reduction in Electron Beams:

Tungsten Alloy is sometimes used in the construction of components for linear accelerators (LINACs) in radiation therapy. Its high density helps reduce the dose delivered to healthy tissues during cancer treatments.

Let’s Talk About Your Project Needs