Molybdenum is a refractory metal known for its remarkable high-temperature strength, low thermal expansion, and excellent corrosion resistance. Among its many forms, metal molybdenum strips are widely used in industrial, aerospace, electronics, and metallurgical applications due to their ability to withstand extreme conditions.

When selecting a molybdenum strip for high-temperature applications, several factors must be carefully evaluated to ensure optimal performance, durability, and safety. These factors include material purity, mechanical properties, thermal characteristics, surface quality, dimensional tolerances, and compatibility with the operating environment. This article explores these considerations in detail, providing a comprehensive guide for engineers, designers, and procurement professionals.

1. Understanding Metal Molybdenum Strips

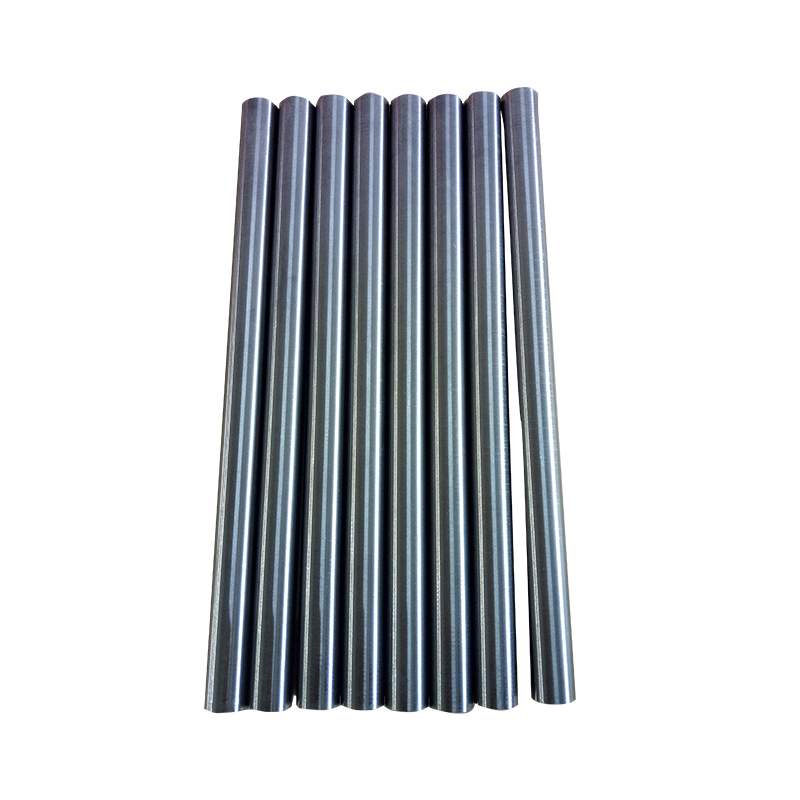

A metal molybdenum strip is a flat, elongated form of molybdenum produced by processes such as rolling, slitting, or extrusion. These strips vary in thickness, width, and length depending on the intended application.

Key properties that make molybdenum strips ideal for high-temperature environments include:

- High Melting Point: Approximately 2,623°C (4,753°F), allowing it to maintain structural integrity under extreme heat.

- Low Thermal Expansion: Minimal expansion reduces thermal stress in precision components.

- High Thermal Conductivity: Facilitates rapid heat dissipation, useful in electronic and industrial applications.

- Corrosion and Oxidation Resistance: Particularly effective in vacuum or controlled atmospheres.

Due to these properties, molybdenum strips are used in heating elements, high-temperature furnaces, electrical contacts, aerospace components, and metallurgical applications.

2. Purity and Alloy Composition

The purity of molybdenum significantly affects its high-temperature performance. Commercial molybdenum typically ranges from 99.95% to 99.99% purity, with minimal amounts of iron, tungsten, and other metals.

Factors to consider regarding purity include:

- Impurities: Elements such as carbon, oxygen, and nitrogen can form oxides or carbides at high temperatures, compromising strength.

- Alloying: Some applications may require molybdenum alloys with small additions of titanium, zirconium, or hafnium to improve creep resistance, thermal conductivity, or oxidation resistance.

Selecting the appropriate grade ensures mechanical stability, oxidation resistance, and long service life under extreme thermal conditions.

3. Mechanical Properties

High-temperature applications impose significant mechanical stress, including tensile, compressive, and creep forces. Therefore, understanding the mechanical properties of molybdenum strips is crucial.

Key mechanical factors include:

- Tensile Strength: Molybdenum strips must withstand stretching or pulling forces without permanent deformation.

- Yield Strength: Indicates the stress level at which the strip begins to deform plastically. High yield strength is essential to avoid structural failure.

- Creep Resistance: Creep refers to slow deformation under prolonged high temperatures. High creep resistance is necessary for applications like furnace components and aerospace parts.

- Ductility: Although molybdenum is inherently brittle at room temperature, its ductility improves with elevated temperatures, making it easier to form or assemble components.

Engineers must carefully match the mechanical property requirements with the operational temperature and load conditions.

4. Thermal Properties

Thermal performance is a primary consideration for molybdenum strips used in high-temperature applications. Important thermal factors include:

a. Thermal Conductivity

High thermal conductivity allows rapid heat transfer, preventing localized hotspots and reducing thermal fatigue. Applications such as electrical contacts and heat sinks benefit significantly from this property.

b. Thermal Expansion Coefficient

Molybdenum has a low coefficient of thermal expansion (~5.2 × 10^-6 /°C). This minimizes dimensional changes under fluctuating temperatures, which is critical in precision components and vacuum environments.

c. High-Temperature Strength

Molybdenum retains excellent strength up to 1,500–2,000°C, making it suitable for furnace components, crucibles, and rocket engine parts.

Selecting a strip with verified high-temperature strength ensures long-term stability and reduced maintenance in extreme environments.

5. Surface Quality and Finish

The surface condition of molybdenum strips affects their performance in high-temperature applications. Considerations include:

- Surface Smoothness: Smooth surfaces reduce stress concentrations, which can lead to cracks or premature failure.

- Oxide Layers: Excessive surface oxidation may weaken the strip or reduce thermal conductivity. Proper storage in vacuum or inert atmospheres before use helps maintain quality.

- Coatings: Some applications require protective coatings (e.g., nickel or molybdenum silicide) to enhance oxidation resistance in air at elevated temperatures.

Ensuring high surface quality improves durability, safety, and efficiency in demanding applications.

6. Dimensional Tolerances

Precise dimensions are critical in applications where molybdenum strips must fit within tight mechanical assemblies. Considerations include:

- Thickness Uniformity: Variations can cause uneven heat distribution or mechanical stress.

- Width and Flatness: Strips must meet exact width specifications and remain flat to ensure proper installation and contact with other components.

- Length Consistency: Especially important in automated production lines or modular assemblies.

Manufacturers often provide customized tolerances for specialized applications to ensure the strip functions reliably under high-temperature conditions.

7. Environmental Compatibility

The operating environment has a direct impact on the performance of molybdenum strips. Key considerations include:

- Atmosphere: Molybdenum oxidizes at high temperatures in air. In applications where oxygen is present, coatings, alloying, or inert atmospheres are recommended.

- Vacuum Conditions: Molybdenum performs exceptionally well in vacuum or controlled gas environments, common in electronics and aerospace applications.

- Exposure to Corrosive Media: Though resistant to many chemicals, prolonged exposure to certain molten metals or reactive gases may necessitate protective coatings.

Matching the strip’s characteristics to environmental conditions prevents degradation and failure.

8. Compatibility with Fabrication Methods

High-temperature components often require additional processing or assembly. The molybdenum strip should be compatible with:

- Cutting and Slitting: Precision cutting ensures proper dimensions without introducing stress cracks.

- Forming or Bending: Strips must maintain structural integrity during shaping.

- Welding and Joining: Molybdenum welding requires high-temperature techniques and compatible filler materials to avoid brittleness.

Understanding fabrication requirements ensures the strip performs reliably in its final application.

9. Cost and Availability Considerations

Although performance is paramount, cost-effectiveness remains an important factor:

- Material Cost: High-purity molybdenum is more expensive but essential for critical high-temperature applications.

- Processing Cost: Precision rolling, coating, and slitting can increase costs.

- Availability: Ensuring consistent supply of specific grades prevents production delays in industrial or aerospace projects.

Balancing performance and cost helps select the most suitable strip for the intended use.

10. Applications of Molybdenum Strips in High-Temperature Environments

Metal molybdenum strips are widely used in applications that demand extreme heat resistance:

- Aerospace: Components in jet engines, rocket nozzles, and thermal shields.

- Electronics: Heat sinks, vacuum tube parts, and electrical contacts.

- Metallurgy: Furnace grids, crucibles, and high-temperature molds.

- Industrial Manufacturing: Heating elements, sensors, and high-temperature rollers.

- Energy Industry: Components in nuclear reactors and solar thermal collectors.

Each application requires a careful balance of thermal, mechanical, and environmental properties, highlighting the importance of proper strip selection.

11. Summary Checklist for Selecting a Molybdenum Strip

To simplify the selection process, engineers should consider the following checklist:

- Material Purity: ≥ 99.95% for high-temperature stability.

- Mechanical Properties: Adequate tensile strength, yield strength, ductility, and creep resistance.

- Thermal Properties: High thermal conductivity, low thermal expansion, and high-temperature strength.

- Surface Quality: Smooth, uniform, and optionally coated for oxidation resistance.

- Dimensional Accuracy: Consistent thickness, width, flatness, and length.

- Environmental Compatibility: Suitability for vacuum, air, or corrosive atmospheres.

- Fabrication Requirements: Compatibility with cutting, bending, and welding processes.

- Cost and Availability: Balance performance with budget and supply stability.

Conclusion

Selecting a metal molybdenum strip for high-temperature applications is a complex process that requires careful consideration of material purity, mechanical and thermal properties, surface finish, dimensional precision, environmental compatibility, fabrication methods, and cost.

By thoroughly evaluating these factors, engineers and designers can ensure that the chosen molybdenum strip performs reliably under extreme conditions, maintaining structural integrity, thermal stability, and long-term durability. From aerospace and electronics to metallurgy and industrial heating, the right molybdenum strip is crucial for operational safety and efficiency.

Advancements in material science, precision manufacturing, and protective coatings continue to expand the capabilities of molybdenum strips, making them an indispensable choice for high-temperature industrial applications worldwide.