Molybdenum strip, a thin, flat form of molybdenum metal, has become an essential material in modern industrial and technological applications. Known for its exceptional thermal stability, electrical conductivity, and mechanical strength at elevated temperatures, molybdenum strip plays a vital role in sectors ranging from electronics and aerospace to glass manufacturing and semiconductor production. But what exactly is molybdenum strip? What makes it so valuable in high-performance environments? And how does it compare to other refractory metals? This article explores the properties, manufacturing process, applications, and future prospects of molybdenum strip in today’s advanced industries.

What Is Molybdenum Strip?

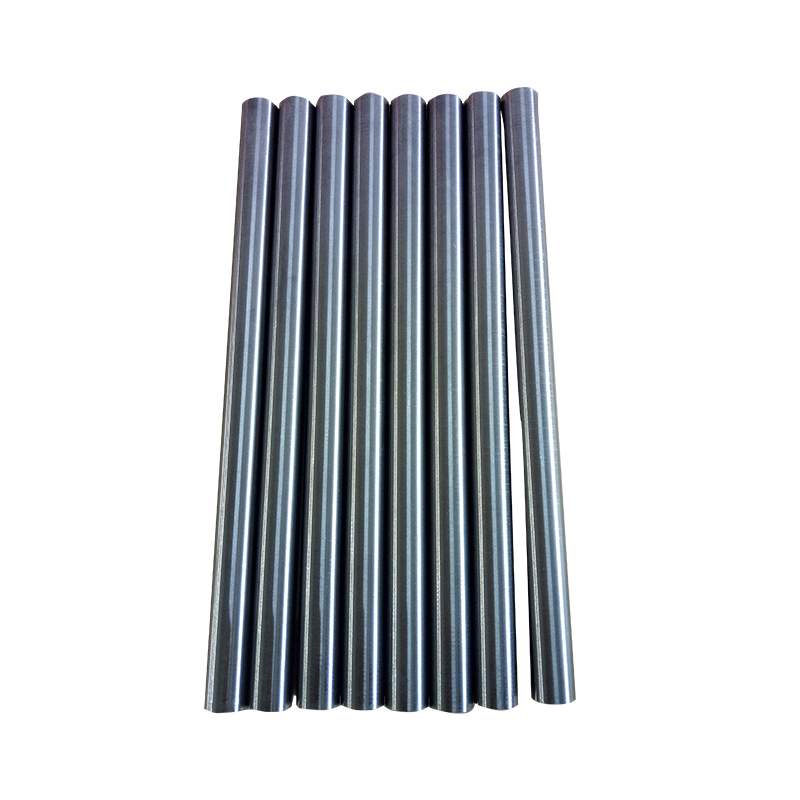

Molybdenum (chemical symbol: Mo) is a silvery-white refractory metal with an atomic number of 42. It has a high melting point of 2,623°C (4,753°F), making it one of the most heat-resistant metals available. A molybdenum strip is a rolled or forged product made from pure molybdenum or molybdenum alloys, typically available in thicknesses ranging from 0.05 mm to 3 mm and varying widths and lengths.

These strips are precision-engineered to meet strict dimensional tolerances and surface finish requirements, ensuring consistency and reliability in demanding applications. Due to molybdenum’s low coefficient of thermal expansion and excellent resistance to thermal shock, molybdenum strips are ideal for environments where dimensional stability under extreme heat is crucial.

Key Properties of Molybdenum Strip

The performance of molybdenum strip stems from its unique combination of physical and chemical properties:

High Melting Point: At over 2,600°C, molybdenum retains its strength and structure at temperatures where most metals would melt or deform.

Excellent Thermal Conductivity: Efficiently transfers heat, useful in heat sinks and thermal management systems.

Good Electrical Conductivity: Makes it suitable for electrical contacts and semiconductor components.

Low Thermal Expansion: Minimizes expansion and contraction under temperature fluctuations, reducing stress in assemblies.

Corrosion Resistance: Resists oxidation and chemical attack in non-oxidizing environments.

Mechanical Strength at High Temperatures: Maintains structural integrity even under prolonged exposure to heat.

These characteristics make molybdenum strip a preferred choice over alternatives like tungsten, tantalum, or stainless steel in many high-tech applications.

Manufacturing Process

Producing molybdenum strip involves several stages:

Powder Metallurgy: Molybdenum oxide is reduced to molybdenum powder using hydrogen gas.

Pressing and Sintering: The powder is pressed into bars or slugs and sintered at high temperatures (around 2,200°C) in a hydrogen atmosphere to form a solid billet.

Hot and Cold Rolling: The sintered billet is hot-rolled to reduce thickness, followed by cold rolling to achieve precise dimensions and smooth surface finish.

Annealing: Heat treatment is applied to relieve internal stresses and improve ductility.

Cutting and Finishing: Strips are cut to required lengths and may undergo surface treatments like polishing or cleaning.

The entire process requires controlled environments to prevent contamination, especially from oxygen, which can embrittle molybdenum at high temperatures.

Major Applications of Molybdenum Strip

Molybdenum strip is used across a variety of high-performance industries due to its reliability under extreme conditions.

Semiconductor Industry: Used as sputtering targets, diffusion barriers, and electrode materials in integrated circuit fabrication.

Flat Panel and Thin-Film Solar Cell Manufacturing: Serves as a back contact layer in CIGS (Copper Indium Gallium Selenide) solar cells due to its adhesion and conductivity.

Glass and Furnace Components: Employed in heating elements, support structures, and seals in high-temperature glass melting furnaces.

Aerospace and Defense: Utilized in missile components, turbine parts, and heat shields where thermal stability is critical.

Electronics and Lighting: Found in halogen lamp supports, cathode assemblies, and transistor bases.

Medical Devices: Used in X-ray tube components and radiation shielding due to its high density and thermal resistance.

Comparison with Other Refractory Metals

To better understand the advantages of molybdenum strip, the following table compares it with other commonly used refractory metals:

| Property | Molybdenum Strip | Tungsten | Tantalum | Niobium (Columbium) |

| Melting Point (°C) | 2,623 | 3,422 | 3,017 | 2,477 |

| Density (g/cm³) | 10.2 | 19.3 | 16.6 | 8.57 |

| Thermal Conductivity (W/m·K) | 138 | 173 | 57 | 54 |

| Electrical Resistivity (nΩ·m) | 53 | 53 | 131 | 152 |

| Coefficient of Thermal Expansion (x10⁻⁶/K) | 4.8 (20–100°C) | 4.5 | 6.3 | 7.1 |

| Oxidation Resistance | Poor above 400°C | Poor above 500°C | Good | Poor |

| Machinability | Moderate | Difficult | Good | Good |

| Cost | Moderate | High | High | Moderate |

As shown, molybdenum offers a balanced combination of high melting point, thermal conductivity, and lower density compared to tungsten and tantalum. While it oxidizes at high temperatures in air, it performs exceptionally well in vacuum or inert gas environments—common in semiconductor and furnace applications.

Challenges and Future Outlook

Despite its advantages, molybdenum strip faces certain limitations. Its susceptibility to oxidation above 400°C requires protective atmospheres or coatings in many applications. Additionally, the mining and refining of molybdenum can have environmental impacts, prompting interest in recycling and sustainable sourcing.

Looking ahead, advancements in alloying—such as adding titanium, zirconium, or lanthanum (e.g., TZM alloy)—are enhancing molybdenum’s creep resistance and high-temperature performance. Moreover, the growth of renewable energy technologies, electric vehicles, and next-generation electronics is expected to drive increased demand for high-purity molybdenum strips.

Conclusion

Molybdenum strip is far more than just a metal component—it is a cornerstone material enabling innovation in some of the most advanced technologies of our time. From powering semiconductor chips to supporting solar energy systems, its unique properties make it indispensable in high-temperature and high-precision environments.

So, what does the future hold for molybdenum strip? As industries push the boundaries of performance and efficiency, this remarkable material is likely to remain at the forefront of material science—proving once again that sometimes, the smallest components make the biggest difference.