In the modern industrial field, tungsten is widely used because of its high melting point, high density and excellent mechanical properties. In addition to traditional pure tungsten materials, tungsten alloy bars have also received more and more attention in recent years. This article will compare tungsten alloy bars with pure tungsten bars and other common metal bars (such as stainless steel, copper, titanium alloy, etc.) in terms of performance, processability, and application fields to help readers understand why tungsten alloys have become an important material choice in the field of high-end manufacturing.

1. Density and strength comparison

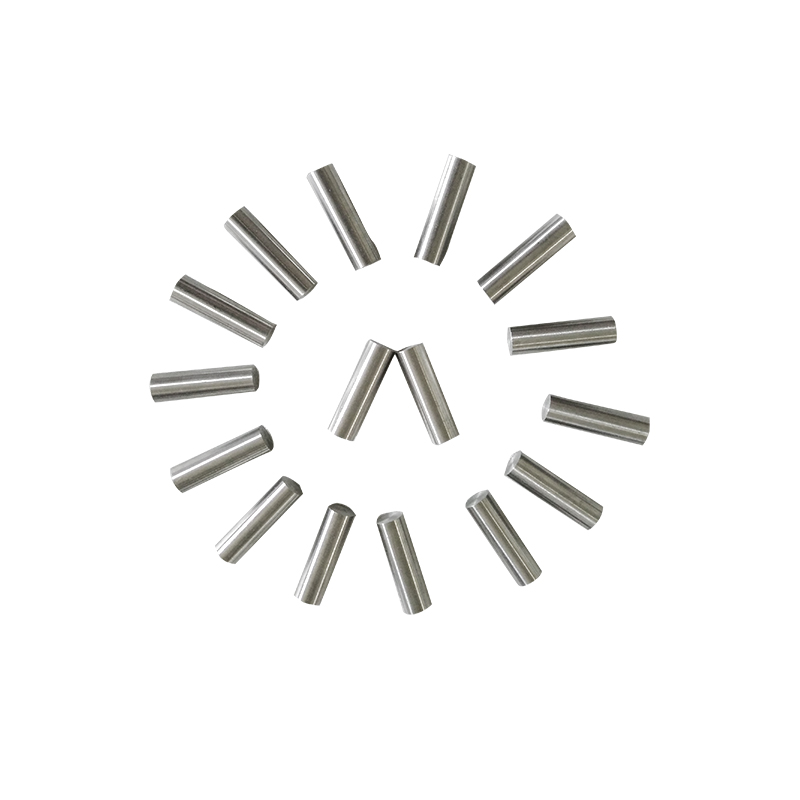

Tungsten has a density of up to 19.3g/cm³, making it one of the heaviest metals in nature. Tungsten alloys usually add nickel, iron, copper and other metals to 90%-97% tungsten, and their density can reach 16.5-18.5g/cm³, which is slightly lower than pure tungsten, but still far exceeds most common metals.

In comparison:

Stainless steel density: about 7.8g/cm³

Titanium alloy density: about 4.5g/cm³

Copper density: about 8.9g/cm³

Tungsten alloy has higher tensile strength and better impact toughness while maintaining high density. It is suitable for occasions that require both high strength and high density, such as counterweights, kinetic armor-piercing projectiles, aviation protective plates, etc.

2. Comparison of processing performance

Although pure tungsten has excellent performance, it is brittle and difficult to machine. It often requires sintering, powder metallurgy and other processes, and is prone to cracking.

In contrast, tungsten alloy significantly improves the ductility and machinability of the material by adding a binder phase (such as Ni-Fe or Ni-Cu), which is suitable for traditional machining methods such as turning, milling, and drilling, which is particularly important for precision manufacturing.

Although other metals such as stainless steel and copper have good processing performance, they are not as durable as tungsten alloys in high temperature and high strength applications.

3. Comparison of high temperature resistance and corrosion resistance

Tungsten melting point: about 3422℃, which is the highest known metal melting point.

Tungsten alloy: retains the high temperature characteristics of tungsten and can work stably for a long time at above 1500℃.

Stainless steel/copper/titanium alloy: usually has a temperature resistance between 300℃ and 600℃, which is far less than tungsten alloy.

In high-temperature vacuum equipment, military nozzles, and aviation heat-resistant parts, tungsten alloy has advantages over other metals.

However, in terms of corrosion resistance, stainless steel and titanium alloy have advantages, while tungsten alloy is more suitable for working in dry and high-temperature environments.

4. Price and comprehensive cost performance

Tungsten alloy is usually more expensive than conventional metal materials such as stainless steel and copper due to its high material cost and processing technology requirements, but compared with pure tungsten, its processing cost is low and the comprehensive cost performance is better.

In applications that need to meet the following requirements, tungsten alloy rods have extremely high cost performance:

High density and small volume

High temperature resistance

Radiation shielding

High strength and fatigue resistance

Tungsten alloy rods have solved the shortcomings of pure tungsten, which are difficult to process and brittle, on the basis of high density, high strength and good processing performance. It is a high-end metal material with extremely balanced performance and application. In the high-tech fields such as aerospace, military industry, medical protection, etc., its advantages far exceed pure tungsten and other traditional metal bars. Although the price is higher, its performance in key applications makes it an irreplaceable solution.