In the world of advanced engineering, precision manufacturing, and defense technology, materials matter. Among the wide array of metal alloys available today, one stands out for its unique combination of density, strength, and durability: the Tungsten Alloy Bar. Whether you're working in aerospace, military, medical, or industrial tooling, tungsten alloy bars are quickly becoming the material of choice for demanding applications.

But what makes this high-density metal bar so exceptional — and why should it be your top choice? Let’s dive into the world of tungsten alloys and uncover their unmatched advantages.

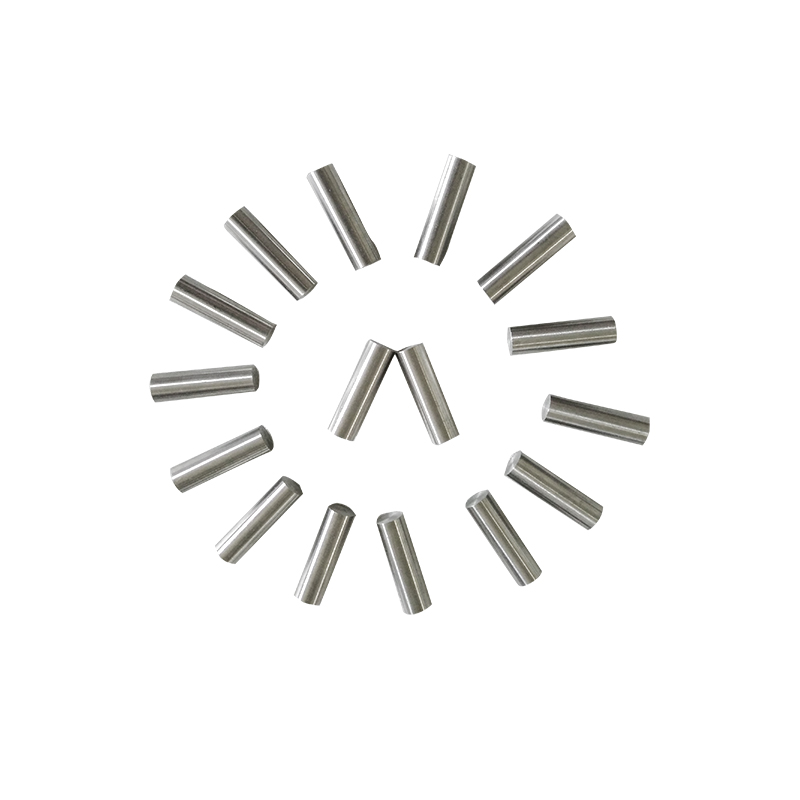

Tungsten alloy bars are available in various sizes, finishes, and custom compositions to suit different applications across industries.

Why Choose Tungsten Alloy Bars?

1. Incredible Density and Weight

Tungsten alloys boast a density of around 17.0–18.5 g/cm³, making them one of the heaviest metals used in engineering. This high density is essential for applications where compact mass is required — such as counterweights, balancing components, or kinetic energy penetrators in defense.

2. Superior Strength and Durability

Tungsten alloy bars can withstand extreme pressure, impact, and temperature. Their resistance to deformation makes them ideal for environments that demand strength under stress — including aerospace components and military-grade projectiles.

3. Excellent Thermal and Corrosion Resistance

Tungsten alloy maintains structural integrity even at temperatures exceeding 1,000°C. It is also resistant to oxidation and corrosion, making it suitable for use in harsh environments, such as oil exploration tools, furnaces, and chemical processing equipment.

4. Non-Toxic Alternative to Lead

Many industries are phasing out lead due to its environmental and health hazards. Tungsten alloy bars offer a non-toxic, eco-friendly alternative without compromising on density — perfect for medical radiation shielding, X-ray collimators, and balancing weights in consumer goods.

5. Outstanding Machinability

Compared to pure tungsten, tungsten alloy bars are easier to machine, cut, and shape — reducing production time and cost. This makes them ideal for use in high-precision tooling, molds, and dies.

Wide Range of Applications

Tungsten alloy bars are used in a broad spectrum of industries:

Aerospace & Aviation: Counterweights in control surfaces, vibration dampers, gyroscope rotors.

Defense & Ammunition: Armor-piercing projectiles, kinetic energy weapons, military shielding.

Medical: Radiation shielding for oncology, CT scanners, and nuclear medicine.

Automotive: Balancing weights in race cars and performance vehicles.

Industrial Tooling: High-strength dies, extrusion tooling, and EDM electrodes.

No matter the industry, when strength, density, and precision are needed, tungsten alloy bars deliver unmatched performance.

From aerospace innovations to medical breakthroughs and industrial durability, the tungsten alloy bar is a material that meets — and often exceeds — the expectations of modern engineering. Its combination of density, strength, and adaptability makes it a smart investment for manufacturers and designers aiming for performance at the highest level.