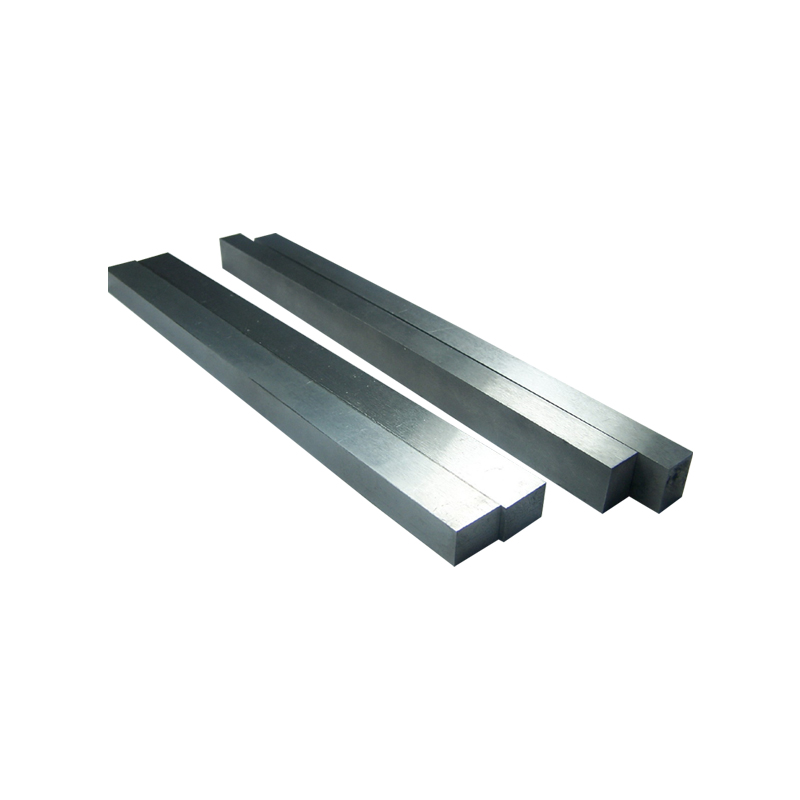

In the steelmaking process, the addition of alloying elements is crucial to improving the performance of steel. Molybdenum, as an important alloying element, is widely used in the steel industry, especially in the production of high-strength and corrosion-resistant steel. Steelmaking Molybdenum Bars, as a key molybdenum alloy material, is increasingly becoming a core component in the field of steelmaking. Its excellent performance makes it play an irreplaceable role in the smelting process, helping to improve the quality and durability of steel products.

Improve the high temperature resistance of steel

Molybdenum can significantly improve the stability and heat resistance of steel in high temperature environments. In some high temperature working environments, such as engine parts, aerospace equipment, etc., the addition of molybdenum can ensure that the steel still maintains good mechanical properties at extreme temperatures.

Enhance the corrosion resistance of steel

Molybdenum has excellent corrosion resistance, especially in chlorine-containing and acidic environments. After adding molybdenum to steel, the corrosion resistance of steel can be significantly improved and its service life can be extended. This makes molybdenum alloy steel widely used in marine engineering, chemical equipment and other fields.

Improve the strength and hardness of steel

Molybdenum alloy steel has higher strength and hardness than ordinary steel. It is often used to make some high-wear-resistant and high-strength steels, such as tool steel and die steel. These steels can still maintain good performance under high load or high wear conditions.

Improve the weldability of steel

The addition of molybdenum can also improve the weldability of steel, reduce cracks and defects that may occur during welding, make the welding process smoother, and ultimately improve the overall performance of steel.

The production process of steel smelting molybdenum rods includes the smelting and purification of molybdenum ore, the synthesis of molybdenum alloys, and the processing and forming of molybdenum rods. The production of molybdenum rods generally adopts the following steps:

Purification of molybdenum ore

Molybdenum ore is first extracted from pure molybdenum by high-temperature smelting. In this process, the molybdenum ore is heated and reacted with a reducing agent to extract molybdenum metal.

Synthesis of molybdenum alloy

Molybdenum is mixed with other alloying elements (such as chromium, tungsten, etc.) and smelted at high temperature to make molybdenum alloys. These alloy components are adjusted according to the performance requirements of steel to ensure that the final steel has the required mechanical properties.

Forming and processing of molybdenum rods

After the molybdenum alloy is melted, it is finally made into molybdenum rods through forging, stretching, cooling and other processes. The diameter, length and surface finish of the molybdenum rod are adjusted according to the specific application requirements to ensure its efficient use in the smelting process.

With the advancement of science and technology and the continuous improvement of steel smelting technology, the production technology of molybdenum rods for steel smelting is also developing. On the one hand, the precision and purity requirements of molybdenum alloy materials are getting higher and higher, and the production process tends to be more efficient and environmentally friendly. On the other hand, with the increasing demand for high-performance and special functional materials in steel products, the application field of molybdenum alloys will be more extensive, especially in the demand for high-end materials in aerospace, high-speed railways, automobile manufacturing and other fields, the application of molybdenum will become more important.

With the increasing shortage of resources, the recycling of molybdenum has become an important direction for future development. The use of advanced recycling technology to reuse molybdenum alloy waste in the smelting process will not only help reduce costs, but also help promote the application of green smelting technology.

As a key alloy material, molybdenum rods for steel smelting have been widely used in many fields, especially in the production of high-end steel, due to their unique properties. With the continuous advancement of technology, molybdenum alloys will play an increasingly important role in improving the performance of steel products and promoting the innovation of smelting technology. In the future, with the further improvement of performance requirements, the market demand and application prospects of molybdenum rods for steel smelting will continue to grow.