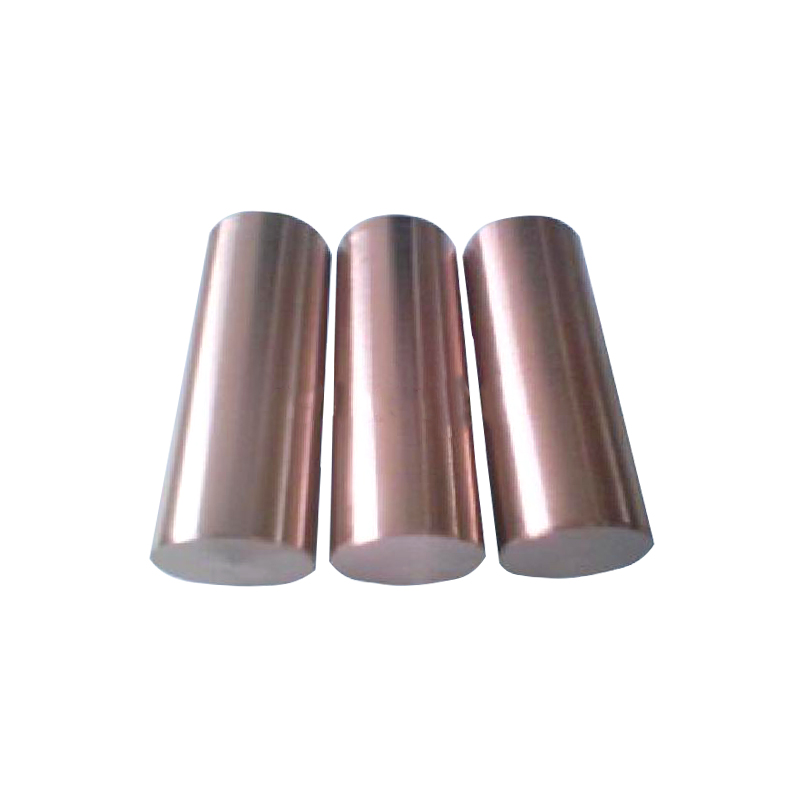

In high-temperature, high-pressure and high-intensity industrial environments, ordinary metals are often unable to cope with harsh working conditions. At this time, a composite material with high melting point, excellent conductivity and good mechanical strength, Tungsten Copper Alloy Cylinder, has become an indispensable component in many high-tech fields.

Tungsten copper alloy cylinder is a common form of this material, which is widely used in the manufacture of key components such as electrodes, contacts, heat sinks and aerospace electronic devices.

Advantages of tungsten copper alloy cylinder

Strong high temperature resistance

Tungsten is one of the metals with the highest melting point (about 3422°C), which gives tungsten copper alloy extremely strong high temperature resistance. Even in extreme environments, such as EDM or vacuum circuit breakers, the structure can remain stable.

Good electrical and thermal conductivity

The addition of copper significantly improves the electrical conductivity and thermal conductivity of the alloy, making it perform well in situations where efficient energy transmission and heat dissipation are required, such as power switchgear and laser cooling components.

Strong resistance to arc erosion

In high-voltage electrical appliances and circuit breakers, arcs can instantly generate extremely high temperatures and cause material ablation. Tungsten-copper alloy can effectively extend the service life of equipment due to its excellent arc resistance.

Strong designability

By adjusting the ratio of tungsten to copper (usually 60%-90% tungsten), alloy cylinders with different performance requirements can be customized to meet the technical indicators of specific applications.

Wide application areas

Electric power and electronics industry: as the core electrode material of vacuum circuit breakers, EDM machines and relays;

Aerospace: used to manufacture rocket nozzles, satellite thermal control devices and high-density counterweights;

Military equipment: used in special materials such as armor-piercing cores and armor protective layers;

Semiconductor manufacturing: as a high-purity heat sink material, it helps chips dissipate heat and prevent overheating damage.

Looking to the future

With the development of new energy, intelligent manufacturing, 5G communications and aerospace technology, the demand for high-performance materials is growing. With its unique comprehensive performance, tungsten-copper alloy cylinders will continue to play an important role in the future of high-end manufacturing and cutting-edge science and technology. At the same time, researchers are also constantly optimizing its preparation process, improving density and reducing costs to promote its wider application.

Tungsten Copper Alloy Cylinder is not only a reflection of the progress of modern industrial technology, but also an important solution to the challenges of extreme working environments. Although it is small in size, it carries many important tasks such as high strength, high conductivity, and high temperature resistance. It can be called a representative of "small size and big energy". In the future, this material will surely show its irreplaceable value in more cutting-edge scientific and technological fields.