Introduction to High-Temperature Arc Welding Electrodes

High-temperature welding requires electrodes that can withstand extreme heat, maintain arc stability, and deliver consistent performance. Molybdenum and tungsten electrodes are two widely used materials in arc welding applications, particularly in TIG (Tungsten Inert Gas) and plasma arc welding. Understanding their differences in material properties, performance, and suitability is essential for selecting the right electrode for industrial and precision welding tasks.

Material Composition and Properties

The choice between molybdenum and tungsten electrodes starts with understanding their fundamental material properties, which influence thermal conductivity, melting point, and durability during high-temperature welding.

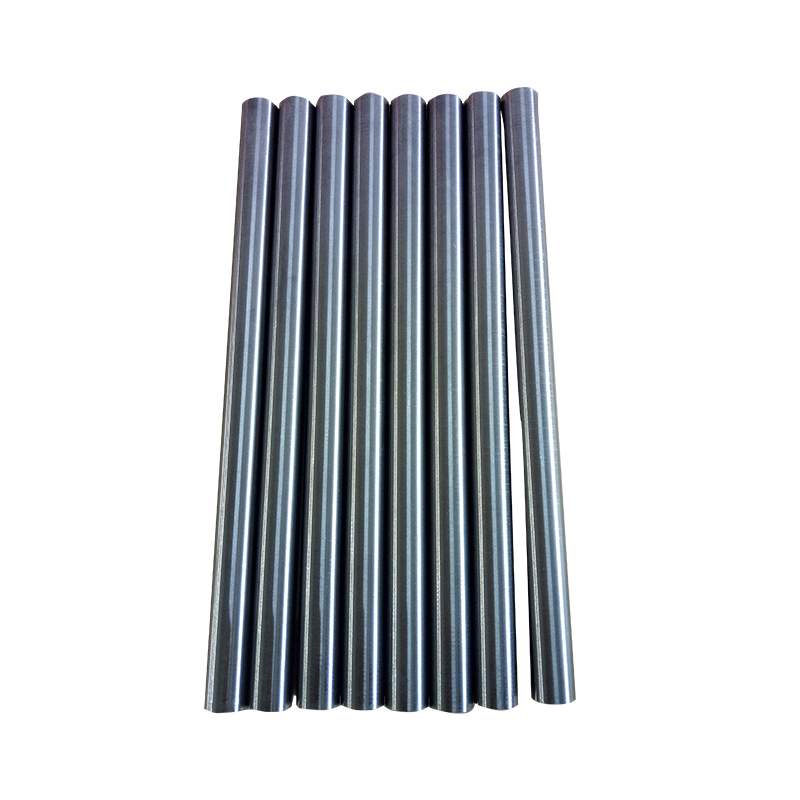

Molybdenum Electrodes

Molybdenum electrodes are made from high-purity molybdenum or molybdenum alloys. They are known for excellent high-temperature strength, low thermal expansion, and good resistance to oxidation. These electrodes maintain their shape and provide consistent arc stability at temperatures exceeding 2,500°C, making them ideal for specialized welding tasks involving stainless steel, nickel-based alloys, and titanium.

Tungsten Electrodes

Tungsten electrodes are composed of pure tungsten or doped variants such as thoriated, ceriated, lanthanated, or zirconiated tungsten. Tungsten offers the highest melting point of any metal (around 3,422°C), excellent arc stability, and low vaporization rates. This makes tungsten electrodes highly versatile for both AC and DC welding, suitable for stainless steel, aluminum, copper, and high-temperature alloys.

Performance in High-Temperature Welding

Both molybdenum and tungsten electrodes are suitable for high-temperature welding, but they exhibit different performance characteristics that affect efficiency and weld quality.

Arc Stability

Tungsten electrodes generally offer superior arc stability, especially for precision TIG welding, due to their high melting point and ability to maintain a concentrated arc. Molybdenum electrodes provide a stable arc but may require more careful current control at extremely high temperatures to avoid deformation.

Heat Resistance

Molybdenum electrodes excel in prolonged high-temperature applications where moderate conductivity and low expansion are needed. Tungsten electrodes handle higher peak temperatures without melting or degrading, making them more suitable for extreme thermal conditions and high-current applications.

Durability and Wear Resistance

Tungsten electrodes, especially doped variants, are highly resistant to wear, reducing electrode replacement frequency and downtime. Molybdenum electrodes are durable but can oxidize or deform under excessive heat if not properly protected with inert gas shielding. For long-term industrial use, tungsten electrodes typically provide better overall longevity.

Ease of Use and Application Considerations

The choice of electrode material also affects usability, project efficiency, and specific welding applications.

Molybdenum Electrode Applications

Molybdenum electrodes are preferred in specialized applications such as welding titanium, nickel alloys, and high-temperature steel where controlled arc heat and minimal contamination are critical. They are also suitable for laboratory and precision work where low expansion and stability are important.

Tungsten Electrode Applications

Tungsten electrodes are widely used in industrial and heavy-duty TIG welding, plasma arc welding, and applications requiring high amperage and extreme temperature tolerance. Their versatility across metals and thicknesses makes them a standard choice for both production and repair work.

Cost and Availability

Tungsten electrodes are more commonly available in various doped forms, providing options tailored to specific welding requirements. Molybdenum electrodes are less common and may be slightly more expensive due to production constraints. Budget considerations and intended usage often influence the choice, especially for large-scale industrial operations.

Comparison Table: Molybdenum vs Tungsten Electrodes

| Feature | Molybdenum Electrode | Tungsten Electrode |

| Melting Point | 2,623°C | 3,422°C |

| Arc Stability | Stable under controlled conditions | Excellent, highly consistent |

| Durability | Moderate, can oxidize at high heat | High, resistant to wear and deformation |

| Best Applications | Titanium, nickel alloys, lab welding | TIG, plasma arc, stainless steel, aluminum |

| Cost | Moderate to high | Varies, widely available |

| Ease of Use | Requires controlled current and shielding | User-friendly with proper setup |

Conclusion

Both molybdenum and tungsten electrodes are highly effective for high-temperature arc welding, but they excel in different scenarios. Molybdenum electrodes are ideal for specialized, precision welding tasks requiring controlled heat and minimal expansion, while tungsten electrodes are better suited for extreme temperatures, heavy-duty industrial work, and high amperage applications. Selecting the appropriate electrode depends on the material being welded, the operating temperature, project scale, and budget considerations. By understanding their unique properties and performance, welders can optimize efficiency, consistency, and weld quality for every high-temperature welding project.